Convective drying process of wood in a gaseous medium - evaporation of moisture from the wood surface

Evaporation of moisture from the wood surface always takes place at a certain temperature, humidity and air velocity. Under normal circumstances, the humidity of the air in the drying kiln is always less than 100%, while the temperature of the air is much higher than normal temperature. Therefore, the equilibrium moisture content of the air is lower than that of the wood surface, and the moisture on the wood surface evaporates into the air. How quickly water evaporates from the wood surface depends on the temperature and humidity of the air. When the air temperature rises or the humidity decreases, the evaporation rate of water on the wood surface is accelerated; on the contrary, the lower the air temperature, the greater the humidity, and the slower the evaporation rate of surface water.

The velocity of the circulating air on the wood surface also has an important influence on the evaporation of moisture from the wood surface. If the air on the wood surface is not flowing, as the water evaporates, a non-flowing saturated water vapor film will soon appear on the wood surface, called the interface layer, and its relative humidity is 100%. It surrounds the wood surface, and if the water on the wood surface continues to evaporate, it can only enter the air through the boundary layer by slow diffusion. At the same time, the boundary layer also hinders the transfer of heat, thereby slowing down the drying rate. For this reason, it is necessary to increase the air circulation speed on the wood surface, blow off the water vapor saturated layer on the wood surface, and keep the moisture evaporation speed on the wood surface within an appropriate range.

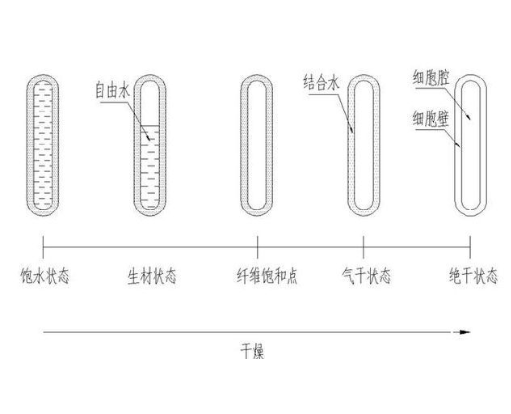

The evaporation of water on the wood surface is also related to the moisture content of the wood. When the moisture content of the wood is above the fiber saturation point, that is, during the period when the free water is mainly evaporated, the evaporation surface is located on the surface of the wood and the lower layers. During this period, if the air If the temperature and humidity remain unchanged, the evaporation intensity of water will remain unchanged. When the free water has evaporated and the adsorbed water has begun to evaporate, the water evaporation will gradually move from the surface of the wood to the interior of the wood, changing to the evaporation of adsorbed water. The heat required for evaporation of unit mass of water is increasing, and the evaporation intensity is tends to decrease.

Fujian Zhangping CHIQIN Technology Co. Ltd, is professional in wood drying over 20 years, covering Aluminum Wood Drying Kiln, Heat Pump Wood Drying Kiln without heat source, Veneer Drying Equipment, Wood carbonization kiln,Food Drying Kiln, Kiln Components etc with high quality and reasonable price. Hope to establish business relationship with you!