Kiln Components

-

Easy Operation Timber Kiln Control System

The kiln control system is divided into two types:semi-automatic control system and automatic control system according to the needs of users.They change the temperature and humudity of the kiln by instrument display and control valve.

Email Details

The temperature is controlled by the change in the amount of vapor sne to the radiator,and the control of humidity is finished by spraying or wetting.The timing reversal of the fan can be achieved by changing the phase sequence of the three-phase power supply of the drag motor. -

Kiln Moisture Discharging System

When the moisture generated in the drying process exceeds the set value,wet motor will open the flap.The moisture is discharged from the positive pressure outlet and fresh air is inhaled from negative pressure import.It finishes the exchange of dry and wet vapor.

Email Details -

Electric Valve System

The stainless steel solenoid valve for heating produced with German patent acts reliably, and is resistant to corrosion and long service life.

Email Details -

Drying Kiln Radiator Kiln Accessories

The radiator is bimetallic structure and the core tube is stainless steel tube.The outside of the tube is aluminum fins.A number of finned tube are parallel welded as a group at both ends of the assembly tube.The numbers of radiators depends on the drying room capacity.Opening heating control system on the pipe system,when the steam passes through the radiator,the radiator will give off the heat to increase indoor temterature and heat the wood.

Email Details -

Aluminum High Temperature ToleranCe Fan Motor

The fan is made of aluminum alloy with accurate die casting, stable in processing and quieter.

Email Details

The fan is with resistance high temperature and high moisture protection.

The fan has the advantage of large air volume, high wind pressure, positive & negative operation. -

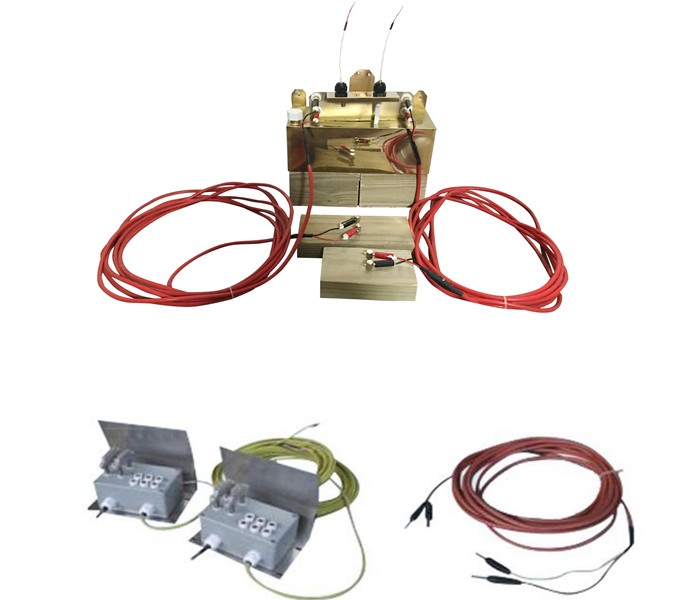

Kiln Probe And Junction Box Kiln Accessories

The probe and Junction box are installed in the kiln.They are used to inspect the temperature and moisture inside the kiln.

Email Details