Effect of Carbonization on Wood Properties

Density reduction

Mainly from the partial loss of hemicellulose. Most studies show that 5-8% of hemicellulose is degraded with little sacrifice in structural strength.

2. Increased Strength

Carbonization at an appropriate temperature will increase the strength of the wood, but excessive and overheated carbonization will reduce the strength.

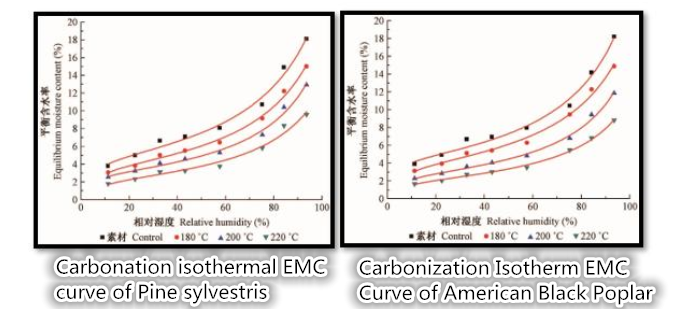

3. Reduced moisture content

All wood absorbs moisture from the atmosphere, and the Equilibrium Moisture Content (EMC) is related to relative humidity and internal structure. Due to the partial loss of hydrophilic groups such as hydroxyl groups during the carbonization process, the ability of wood to absorb water is reduced.

Therefore, carbonized wood not only has lower EMC at a given relative humidity, but also reduces the increment of EMC with the increase of relative humidity, so the wood is not easy to expand and shrink in volume.

As can be seen from the chart above, carbonized wood is significantly less sensitive to humidity, which gives it better stability

Carbonization can improve the dimensional stability of wood and remove or slow release the internal stress of wood. The reason is that after chemical changes in hemicellulose, especially polyglucuronide, it becomes a weakly hygroscopic monomer; in addition, the hydroxyl groups in the cellulose molecular chain interact with each other. combine to form hydrogen bonds.

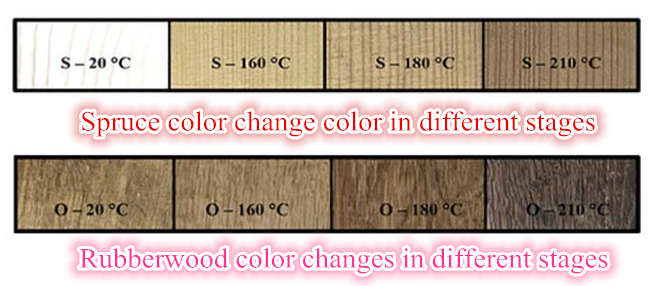

4. Color deepening

As can be seen from the graph above, the color becomes darker as the carbonization temperature increases. The change in the color of carbonized wood is mainly caused by the change of compounds, the degradation of hemicellulose, lignin and some extractive compounds.

5. Improved anti-corrosion ability

The possible reason why carbonization improves the antiseptic performance of wood is that during the carbonization process, the composition of wood changes, which cuts off the source of nutrients needed for the survival of fungi; at the same time, the reduction of moisture content inhibits the growth of fungi, so that the corrosion resistance can be improved. improve.

Fujian Zhangping CHIQIN Technology Co. Ltd, is professional in wood drying over 20 years, covering Aluminum Wood Drying Kiln, Heat Pump Wood Drying Kiln without heat source, Veneer Drying Equipment, Wood carbonization kiln,Food Drying Kiln, Kiln Components etc with high quality and reasonable price. Hope to establish business relationship with you!

- Aluminum Wood Drying Kiln

- New Type Steaming Heated Kiln for Wood Dryer

- Hot Water Drying Chamber For Wood Drying Machine

- Heat Transfer Oil Drying Kiln Drying Equipment

- Natural Gas Drying Kiln For Wood Dryer Machine

- Radiata Pine Drying Kiln Drying Chamber For Wood

- Rubber Wood Drying Kiln Timber Drying Chamber

- Rosewood Drying Kiln Channel Kiln For Wood

- Bamboo Drying Kiln Drying Machine

- Intelligent Wood Drying Kiln With Easy Operation

- Heat Pump Drying Kiln

- Heat Pump Wood Drying Kiln Dryer Without Boiler

- Heat Pump Drying Kiln for food

- Veneer Drying Equipment

- Track Veneer Drying Kiln

- Veneer Roller Dryer machine

- 3-layer Net-Belt Veneer Dryer for wood

- Wood carbonization kiln

- High Frequency Vacuum Wood Carbonizating Kiln

- Special kiln for carbonization of bamboo chips