How wood drying equipment works

Do you know how wood drying equipment works? let me tell you.

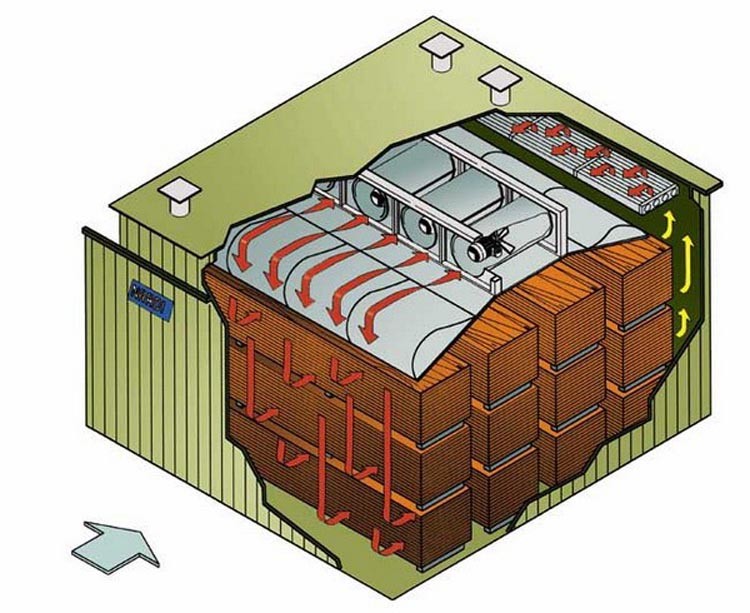

When the drying chamber is in normal operation, the fuel is fully burned in the combustion chamber to generate thermal energy, which is fully absorbed by the drying medium in the thermal energy drying system, resulting in a temperature of about 170 degrees Celsius. The system transports high-temperature hot air into the drying room to dry the wood; at the same time, the steam generator on the equipment can generate a large amount of normal pressure steam. According to the requirements of the drying process, the steam can be timely sent into the drying room to spray the wood. Steaming and humidity conditioning treatment, the humidity conditioning system is an independent steam system and is equipped with safety devices. The wood drying kiln first evaporates the moisture on the surface of the wood, the moisture content of the surface layer is lower than that of the interior of the wood, and the moisture inside moves to the surface layer under the action of the moisture content gradient. The speed of drying in the early stage depends on the speed of water evaporation on the surface of the wood. In the middle and late stages of drying, the drying speed depends on the movement speed of water inside the wood, which is inversely proportional to the thickness of the board and the specific gravity of the wood. In addition, sapwood dries faster than heartwood. The chord tops of hardwoods dried faster than the diameter tops; however, the differences in the chord diameters of conifers were less pronounced. The drying effect of the wood dryer is also greatly affected by the tree species.

If you are interested in wood drying equipment, welcome to contact me.

- Aluminum Wood Drying Kiln

- New Type Steaming Heated Kiln for Wood Dryer

- Hot Water Drying Chamber For Wood Drying Machine

- Heat Transfer Oil Drying Kiln Drying Equipment

- Natural Gas Drying Kiln For Wood Dryer Machine

- Radiata Pine Drying Kiln Drying Chamber For Wood

- Rubber Wood Drying Kiln Timber Drying Chamber

- Rosewood Drying Kiln Channel Kiln For Wood

- Bamboo Drying Kiln Drying Machine

- Intelligent Wood Drying Kiln With Easy Operation

- Heat Pump Drying Kiln

- Heat Pump Wood Drying Kiln Dryer Without Boiler

- Heat Pump Drying Kiln for food

- Veneer Drying Equipment

- Track Veneer Drying Kiln

- Veneer Roller Dryer machine

- 3-layer Net-Belt Veneer Dryer for wood

- Wood carbonization kiln

- High Frequency Vacuum Wood Carbonizating Kiln

- Special kiln for carbonization of bamboo chips