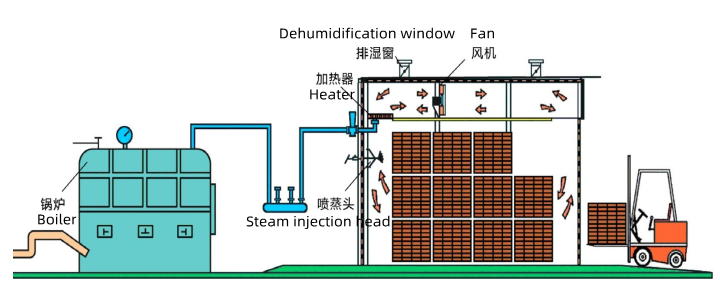

"Illustration" of the whole process of wood drying

The above picture is a schematic diagram of the wood drying process. The wood waste collected during the wood processing process is burned in the boiler to provide thermal resources for the wood drying kiln. Due to insufficient combustion during the use of the boiler, which does not meet the requirements of environmental protection, electric heating can be used to provide thermal resources.

The wood drying kiln is mainly composed of a kiln body, a control system, a heating system, a humidity control system, a fan and a humidity extraction window. In the top fan drying kiln, in order to circulate the heat, a certain height of false ceiling must be set aside. The fan is placed on the false ceiling, and the heat emitted by the rear heater is circulated up and down to the whole kiln. The air is circulated back and forth, and the air circulation chain of the entire kiln body is formed at this time.

When the drying medium in the kiln is dry or wet, switch the exhaust window to adjust the medium humidity. When the drying medium in the kiln is always in a dry state, it is necessary to adjust the humidity in the kiln through the steam jet to prevent the wood from cracking during the drying process.

The wood drying process is essentially the process of heat and moisture exchange between the wood medium and the wood, and the wood drying process is monitored by controlling the temperature and humidity of the medium. Our company has independently developed semi-automatic and fully automatic control systems for wood, which can control the entire drying temperature and humidity, wood moisture content and fan operation to ensure drying quality.

The design, production, installation and operation of the entire drying chamber is an extremely complex process, and needs guidance. Our company will not only design the drying kiln according to your wood species, plate thickness and drying needs, but more importantly, select a suitable drying kiln for you. The drying benchmark, to provide you with drying guidance, welcome to inquire.

- Aluminum Wood Drying Kiln

- New Type Steaming Heated Kiln for Wood Dryer

- Hot Water Drying Chamber For Wood Drying Machine

- Heat Transfer Oil Drying Kiln Drying Equipment

- Natural Gas Drying Kiln For Wood Dryer Machine

- Radiata Pine Drying Kiln Drying Chamber For Wood

- Rubber Wood Drying Kiln Timber Drying Chamber

- Rosewood Drying Kiln Channel Kiln For Wood

- Bamboo Drying Kiln Drying Machine

- Intelligent Wood Drying Kiln With Easy Operation

- Heat Pump Drying Kiln

- Heat Pump Wood Drying Kiln Dryer Without Boiler

- Heat Pump Drying Kiln for food

- Veneer Drying Equipment

- Track Veneer Drying Kiln

- Veneer Roller Dryer machine

- 3-layer Net-Belt Veneer Dryer for wood

- Wood carbonization kiln

- High Frequency Vacuum Wood Carbonizating Kiln

- Special kiln for carbonization of bamboo chips