Parameters during wood drying

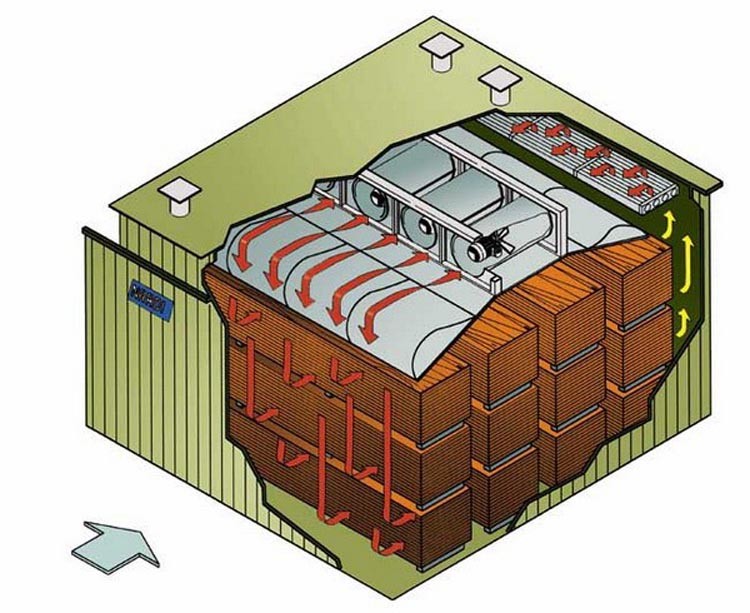

The most important thing in the wood drying process is to make the parameters in the drying equipment as close as possible to the drying benchmark. The most important parameters in the wood drying benchmark are wood moisture content, air temperature and humidity.The flow rate of air passing through the pile is also one of the main parameters affecting the drying quality of wood, and the heating area ratio in the drying chamber is the main parameter affecting the heating rate. However, when the drying equipment is installed (except for equipment equipped with variable frequency motors), the flow velocity of the air has been determined, and the ratio of the heater will not change. During the heating process, only the pressure of the heating steam and the The influence of external air exchange (the temperature of the external air is related to the air intake temperature and the heat loss of the drying room during ventilation; the humidity of the external air directly affects the drying rate and the ability of the hot air as a heating medium to carry moisture), the current control technology It has not been refined to this extent, so during the drying process, it is mainly to monitor the moisture content of the wood, the temperature and humidity of the humid air in the drying room.

The control objectives of the wood drying control system, namely the moisture content of the dry wood, the temperature and humidity in the drying room, these three are only the control parameters on the surface. In fact, it is necessary to start from the overall drying quality, and control the appearance, drying stress, moisture content uniformity and reduce drying defects of the wood according to specific benchmarks.

The control of wood drying is to adjust the operable components and equipment parts manually or automatically, so as to compensate the influence of various interference factors on the drying process, so that each variable is within the expected range and as close as possible to the desired value. The established wood drying reference parameter values, so as to ensure that the wood drying quality is as close as possible to the expected value.

Fujian Zhangping CHIQIN Technology Co. Ltd, is professional in wood drying over 20 years, covering Aluminum Wood Drying Kiln, Heat Pump Wood Drying Kiln without heat source, Veneer Drying Equipment, Food Drying Kiln, Kiln Components etc with high quality and reasonable price. Hope to establish business relationship with you!

- Aluminum Wood Drying Kiln

- New Type Steaming Heated Kiln for Wood Dryer

- Hot Water Drying Chamber For Wood Drying Machine

- Heat Transfer Oil Drying Kiln Drying Equipment

- Natural Gas Drying Kiln For Wood Dryer Machine

- Radiata Pine Drying Kiln Drying Chamber For Wood

- Rubber Wood Drying Kiln Timber Drying Chamber

- Rosewood Drying Kiln Channel Kiln For Wood

- Bamboo Drying Kiln Drying Machine

- Intelligent Wood Drying Kiln With Easy Operation

- Heat Pump Drying Kiln

- Heat Pump Wood Drying Kiln Dryer Without Boiler

- Heat Pump Drying Kiln for food

- Veneer Drying Equipment

- Track Veneer Drying Kiln

- Veneer Roller Dryer machine

- 3-layer Net-Belt Veneer Dryer for wood

- Wood carbonization kiln

- High Frequency Vacuum Wood Carbonizating Kiln

- Special kiln for carbonization of bamboo chips