Stress and deformation during wood drying——The internal stress of wood drying and its causes

The stress that appears on the wood section under the action of external force is called external stress, and the stress inside the wood without external force is called internal stress. The cracking and deformation of wood without any external force proves that there is indeed internal stress inside the wood. For example, the cracking of wood is caused by the destruction of wood tissue due to the tensile stress inside the wood exceeding the tensile strength limit of wood.

The internal moisture distribution of freshly felled wet wood is uniform, there is no moisture content gradient, and there is no internal stress. However, when wood is naturally dried in the atmosphere, uneven shrinkage will occur and internal stress will occur. For example, the water on the surface of wood evaporates quickly, and its moisture content first drops below the fiber saturation point, and the surface begins to shrink. However, the moisture content of the inner layer is still above the fiber saturation point, and no shrinkage occurs. In this way, the outer layer shrinks, and the inner layer does not shrink, resulting in internal stress of external tension and internal compression. The difference between the chord shrinkage and the radial shrinkage of wood will also cause internal stress.

The cause of internal stress in wood during drying is due to the deformation of wood cell lumen and cell wall below the fiber saturation point. During the drying process, defects such as bending and cracking of wood are the specific manifestations of internal stress.

The internal stress of wood is caused by the uneven moisture content inside the wood and the uneven drying shrinkage caused by it. The uneven distribution of moisture content in wood will cause temporary stress and deformation. After the moisture content is uniform, the stress and deformation will disappear. This stress is called moisture content stress or elastic stress, and this deformation is called moisture content deformation or elastic deformation. In addition to being elastic, wood also has plasticity. During the continuation of moisture stress and deformation, the outer or inner layers of wood will undergo plastic deformation due to the action of hot and humid air. After the moisture content is evenly distributed, the plastically deformed part will be fixed and cannot return to the original size, nor can it be reduced to the size that should shrink, and maintain a part of the stress. This deformation is called residual deformation, and this stress is called residual stress.

The sum of the moisture content stress and the residual stress inside the wood is equal to the total stress of the wood.

In the process of wood drying, it is the total stress that affects the quality of wood drying. After the drying process is over, it is the residual stress that continues to affect the quality of the wood. In order to ensure the quality of the wood, the smaller the two kinds of stress, the better.

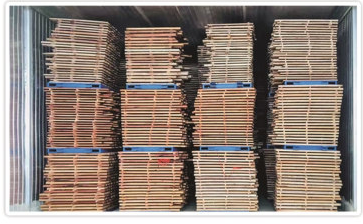

Fujian Zhangping CHIQIN Technology Co. Ltd, is professional in wood drying over 20 years, covering Aluminum Wood Drying Kiln, Heat Pump Wood Drying Kiln without heat source, Veneer Drying Equipment, Wood carbonization kiln,Food Drying Kiln, Kiln Components etc with high quality and reasonable price. Hope to establish business relationship with you!