Energy Saving Veneer Roller Dryer Machine

- Chiqin

- China

- One month after receiving the moneY

- 10 sets per month

Purpose:

This machine is a main equipment to produce plywood.It is especially suitable for drying thick veneer.

Energy Saving Veneer Roller Dryer Machine

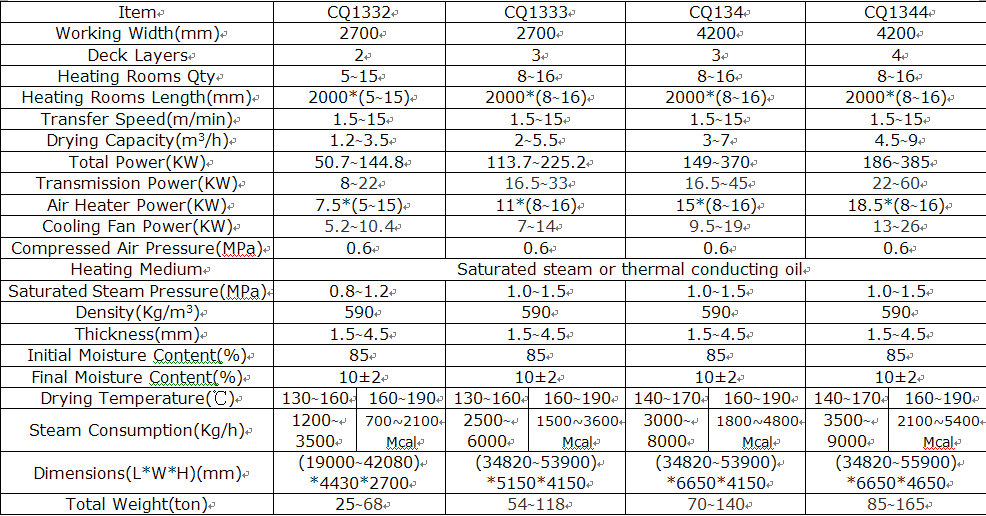

Main specification:

CQ1332 Two layers of veneer roller dryer

CQ1333 Three layers of veneer roller dryer

CQ134 Three layers of veneer roller dryer

CQ1344 Four layers of veneer roller dryer

Characteristics:

CQ13 Series Veneer Roller Dryer adopts lots of high-tech and advanced technical control technology.It has the features of high efficiency,energy saving ,good drying effect and so on.The air flow is circulated horizontally and sprayed vertically to dry the veneer in machine.Veneer are transferred by couples of rollers.

Main specification and technical parameters:

Advantage:

1. Low energy consumption. High thermal efficiency and low power consumption;

2. Less investment. Using wood processing residues as fuel, the drying cost is low;

3. It is convenient to adjust humidity, and the effect of heat and humidity treatment is good. The air circulation is uniform, and the drying quality of the wood is better;

4. Simple operation, easy maintenance;

5. Light weight, movable, mold fast. Easy to install and debug.

Guarantee

The equipment is guaranteed for one year.

1.We provide free spare parts and maintenance service if there is problem with the equipment in one year.

2.You need to pay for the spare parts and necessary maintenance service when there is problem with the equipment after one year.

3.Our company provides necessary wood drying technology and special technical service to meet the requirements of customers.

After-sale Services

Our company is in charge of the installation and debugging of the equipment.Our technical workers will finish it until all the equipment runs properly.

Patent and Certificate:

Factory Show

Most commercial timber can be dried as designed, such as as ash, pine, larch, birch, beech, elm, maple, oak or high moisture content wood. Users of wood drying kilns include housing constructions, furniture manufacturers, decking and flooring manufacturers, and other woodworking factories and companies for solid cloth hanger, wood photo frames....more