High Temperature Thermal Treatment Kiln

- china

- 15-20days

- 10sets per month

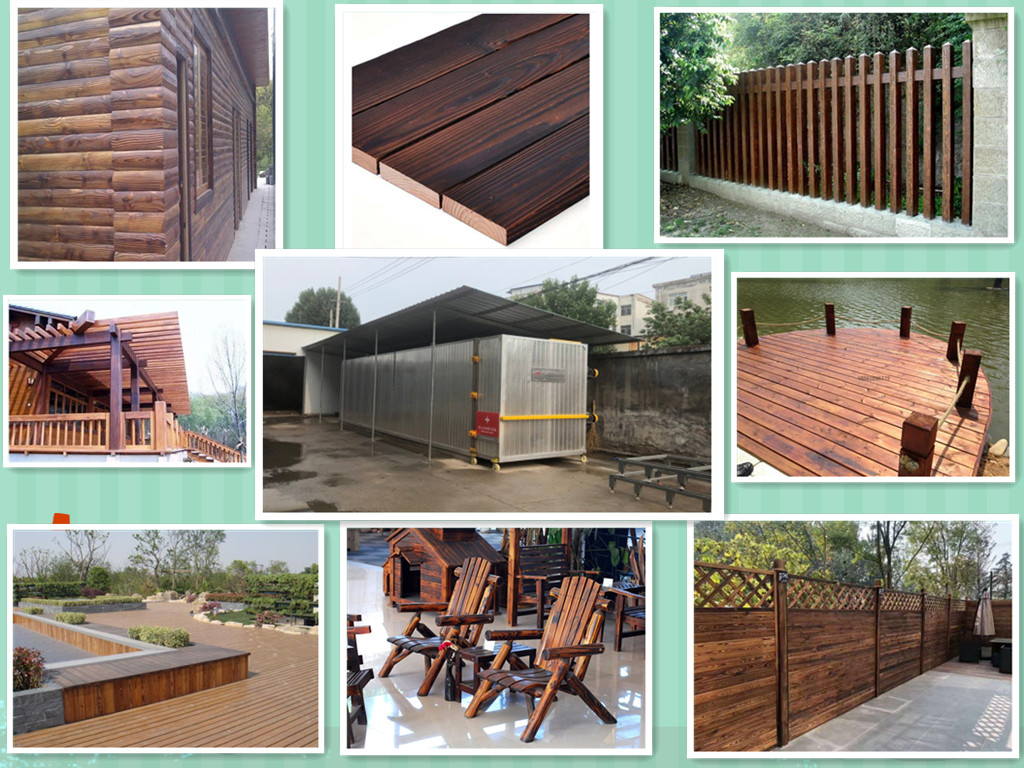

Wood Treated by Green Fire Wood Charring Equipment:

●Material size is stable, not easy to crack, not easy to deform.

●Products are more sensory, increase the plane texture three dimensional sense.

●Clean indoor air, only absorbed, not released.

●Improve unit capacity making material and processing efficiency is higher.

●Reduce cost consumption and increase production efficiency by at least: 40%

●Tamp product quality, after - sale service is reduced by a minimum of 60%

High Temperature Thermal Treatment Kiln

Characteristics of Wood Deep Carbonization Equipment:

●High temperature setting: improve the stability of the geometric size of wood- -not easy to crack or to deformation, pure French high temperature processing technology.

●Convenient processing: wood carbonization is more convenient for post- processing.

●Physical replacement: completely degreasing, sugar removal, oil removal and insecticidal.

●Color transformation simple and gorgeous, uniform, adjustable depth.

●Physical method: without any chemical additions, low carbon, environmental protection, and recyclable.

●Weatherproof and corrosion protection improve the weather resistance of wood, and achieve the physical preservation of wood.

●Unique process: coniferous material can be directly carbonized water board, without pre-drying.

●Complete terrain:; the carbonized wood can adapt to a variety of indoor and outdoor environment

●Green environmental protection: waste water, waste gas“0" discharge.

●Control modes: automatic touch.

●Heating methods : heat conducting oil boiler, electric heating.

●Loading methods : rail type.

●Installation methods : achine transport, on-site production.

●Designed temperature :≤240 °C.

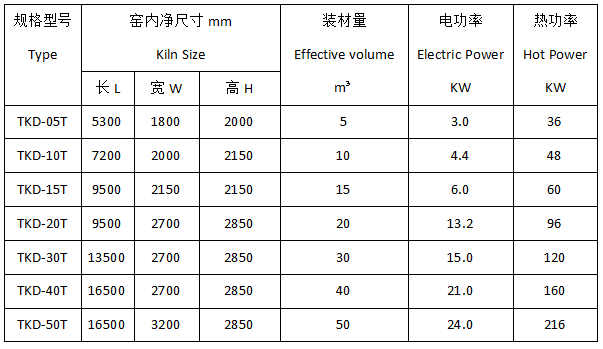

●Effective volume: 10 - 100 cubic meters (actual loading).

●Requirements of civil engineering : ground flat floor, no additional construction foundation.

●Private customization: according to user needs, a variety of configuration options, one hour to provide a complete plan.

Wood deep carbonization equipment technical parameters

Patent and Certificate:

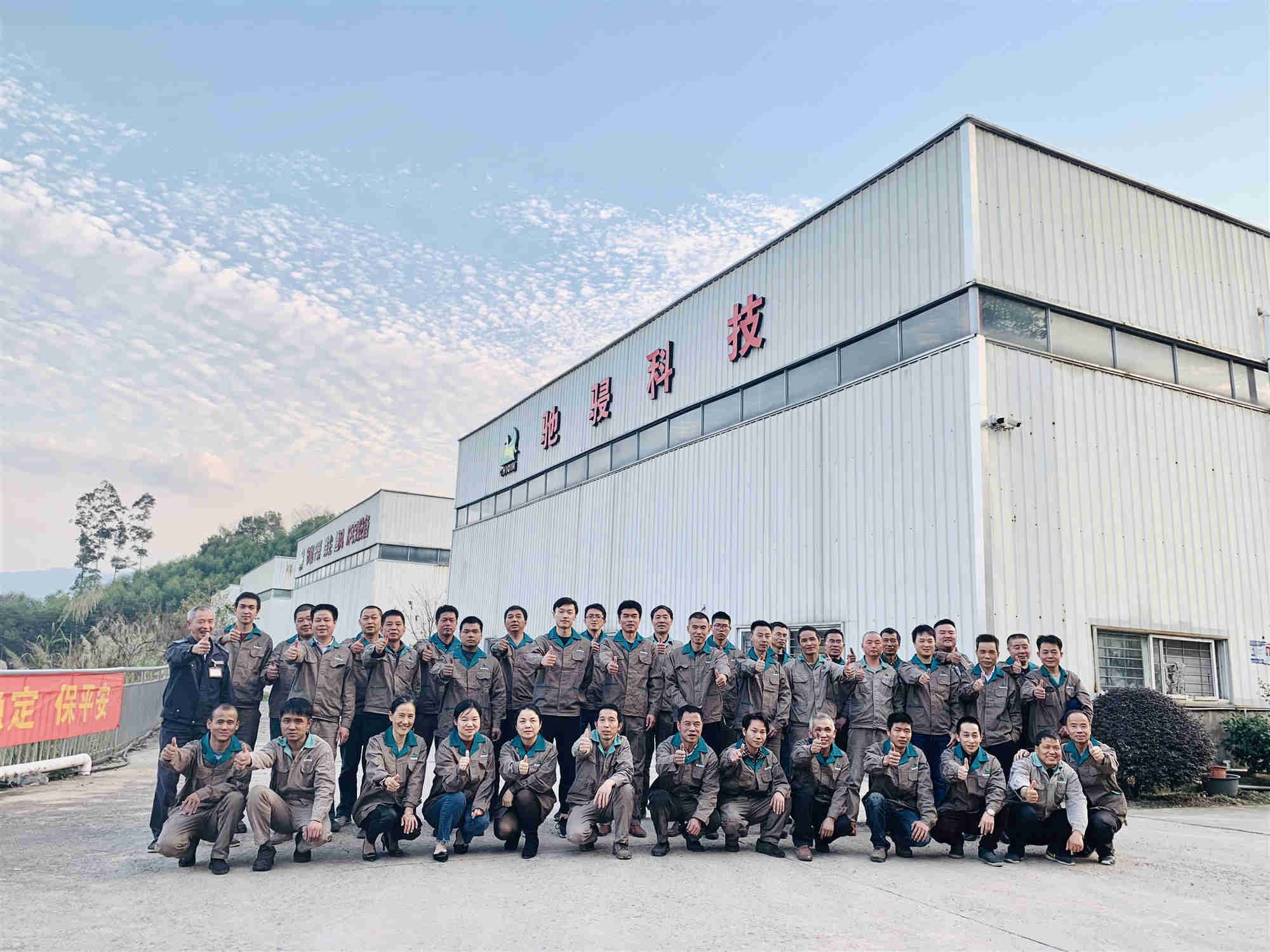

Factory Show

Most commercial timber can be dried as designed, such as as ash, pine, larch, birch, beech, elm, maple, oak or high moisture content wood. Users of wood drying kilns include housing constructions, furniture manufacturers, decking and flooring manufacturers, and other woodworking factories and companies for solid cloth hanger, wood photo frames....more